Technology to the Point

The Mars Series

INTELLIGENT+ DYNAMIC+ INTERACTIVE+

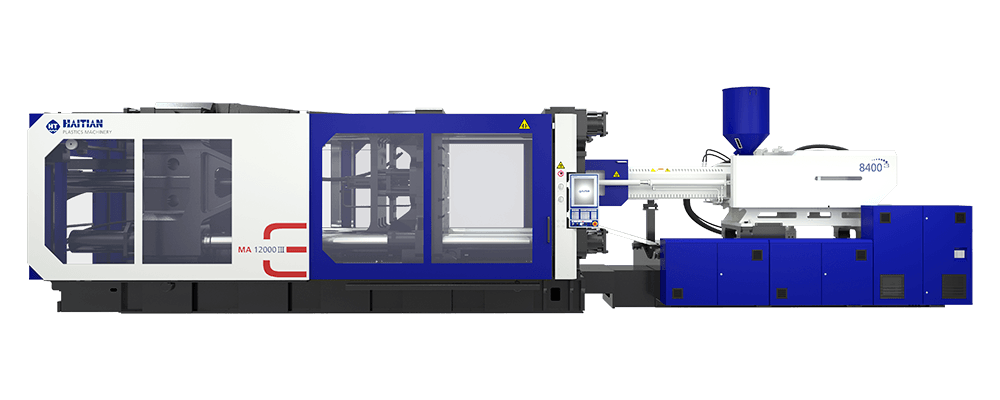

The new generation of our bestseller is more powerful than ever thanks to significant improvements. New motors and intelligent motion control provide more precise processes in a wide application field like consumer goods, toys or construction. Optimized core components such as the closed-loop injection unit increase the efficiency and production quality of the world‘s most successful injection molding machine.

Clever software concepts complement the newly-formed hardware base with all common interfaces for open connectivity with smart manufacturing solutions. The intelligent answer to the growing demands in the plastics processing industry – and modern response to the environmentally relevant challenges of our time. The new Mars III Series is extremely energy-efficient, economically and very attractive in terms of price/performance ratio. Technology to the Point like never before.

MA III Series

Sold more than 350,000 times

- Available from 600 to 33,000 kN

- World’s best-selling injection molding machine

- New high-drive servo system (developed by Haitian)

- Fully improved design structure

- Full closed-loop process, high repeat accuracy

- Energy saving

- Interactive with open integration