Haitian Power Battery Shipping Solution, Escorting Safety and Efficiency

2023-03-21

Having developed rapidly in recent years, new energy vehicles have activated the trillion-dollar blue ocean market. As the core component of new energy vehicles, power batteries play a vital role in developing the new energy vehicles, including rapidly driving the industry’s strong demand for lithium-ion power batteries and the accelerated development of emerging technologies such as sodium-ion batteries.

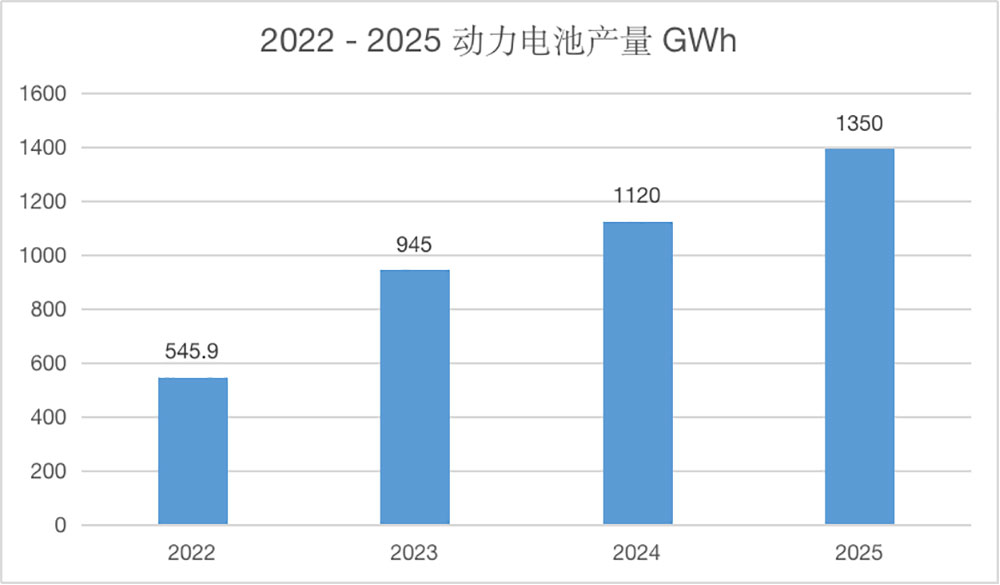

As reported on www.cinic.org.cn, China’s new energy vehicle market will grow at a compound annual growth rate of more than 40% in the next five years, and the output of power batteries will exceed 1,350 GWh, significantly increasing battery shipments.

In addition, after the CATL German factory is built, enterprises such as CALB and EVE are entering the European market. In this case, China’s overseas sales of power batteries will also reach a new height.

The energy density of the battery materials of the leading power battery manufacturers is converging to more purse the bulk density, making the power battery manufacturers to pay more close attention to the square, cylindrical and pouch battery. From the perspective of the market share of the three, the installed capacity of square battery occupies an absolute dominant position because BYD and CATL use square batteries in China. However, the proportion of the three types in foreign countries is close, but cylindrical batteries have a higher growth trend because of Tesla.

- Square battery is characterized by high packaging reliability, high system energy efficiency, and relatively good stability. However, there are too many models on the market, and there is a problem that the system life is much lower than the life of the monomer.

- Cylindrical battery is characterized by mature process, low PACK cost and heat dissipation performance better than that of square batteries, but it still has to face problems such as difficult heat dissipation design and low energy density after grouping.

- Pouch battery is packaged by aluminum plastic film for good safety, light weight and longer cycle life, but its production efficiency is low and its cost is high.

Other special forms such as Pack (integrated) and blade batteries will not be discussed here due to space reasons.

With the gradual development of the power battery industry towards scale, cooperation and intelligence, the development of power batteries and related upstream and downstream supporting industries also has a broader space. However, a series of shipping package problems arise accordingly:

- How to ensure the safety of the battery during intermediate storage and shipment when the power battery is shipped from the production line to being assembled on the vehicle in the vehicle factory?

The ex-service old batteries are more prone to thermal runaway due to the damaged electrode material structure subject to multiple charges and discharges. Safety guarantee for the shipment and storage of ex-service batteries:

- How to establish a standard recycling process with the safety and efficiency of the ex-service batteries guaranteed?

According to the current actual situation, most of the ex-service batteries have intact structural functions and meet the testing provisions stipulated in China. With the most importance attached to basic packaging (pallet or wooden case), more mature battery shipment solutions are not yet widely used.

For the safety and efficiency requirements of power battery shipping package, Haitian has developed a wide range of professional solutions tailored to the power battery vehicle industry, aiming to quickly respond to customers and manufacture special boxes. Next, let’s introduce the Haitian Special Logistics Machinery to battery shipment solutions.

Haitian Special Logistics Machinery: Battery Shipment Solutions:

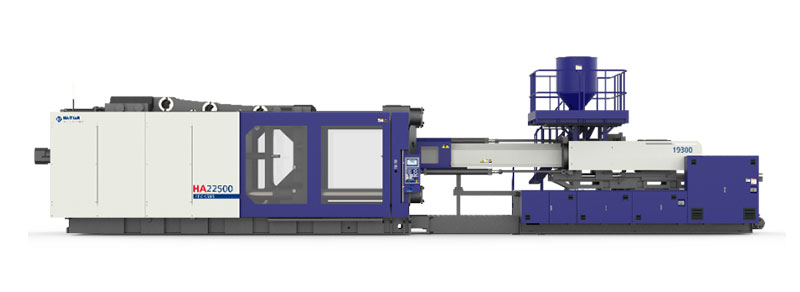

- Model: HA22500/35000 Pegasus

- Product: Cell pallet

- Weight: 12 kg

- Cavity: 1

- Raw material: PP+15%GF

- Period: 96 s

- Feature: 196 cavities in the cell

- Product size: 900*900*250 mm

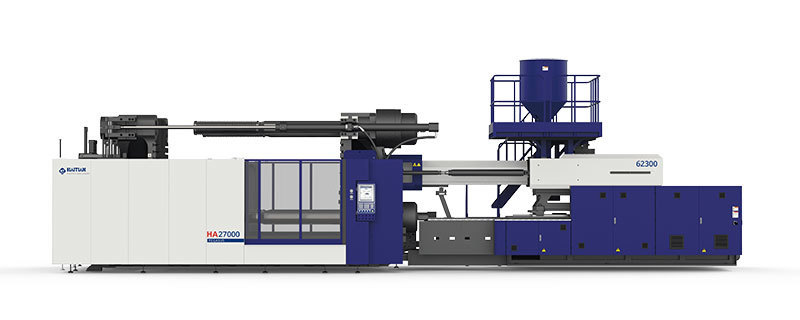

- Model: HA27000/62300 Pegasus

- Product: Cell pallet of Square Shell

- Weight: 20 kg

- Cavity: 1

- Raw material: PP/PA+25%GF

- Period: 167 s

- Feature: 2*28 cavities in the cell

- Product size: 1400*820*250 mm

Highlights:

-

Various models to meet diverse needs

There are various types of special logistics, which can be selected according to different battery cell specifications.

-

Excellent ability to empower space

Large mold thickness and injection volume can ensure the production of heavy vehicles, and more batteries can be embedded. With strong bearing capacity and far more stacking layers than similar products, it helps to realize three-dimensional storage and improve space utilization efficiency.

-

Better performance and lower cost

Compared with traditional metal pallet, it reduces the cost by more than half, and it has stronger corrosion resistance, moisture resistance and wear resistance than wooden pallets.

-

Safe and stable property and better quality

In addition to high manufacturing accuracy and stable quality, it has embedded void for battery, which meets the safety requirements of the shipment and it is conducive to rapid loading and unloading.

-

Optimize the design to meet the production

The plasticized component is optimized to meet the scope of application where 5% to 50% of the glass fiber is added to the raw material.

-

More expansion for no worries

In the future, the online glass fiber mixing process can be expanded, realizing the online mixing of glass fiber and resin, improving the quality of finished products and reducing production costs.